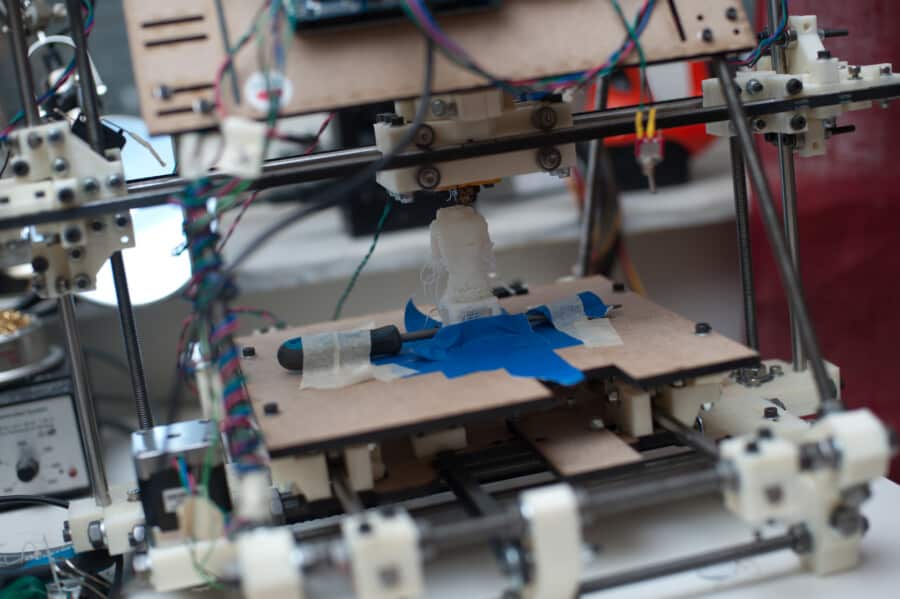

The very first layer of your design must be firmly bonded to the printer’s print bed in order for the subsequent layers of your print to be constructed on top of it. Further issues will arise if the first layer does not adhere to the print bed. We will study and discuss the various reasons for each of these first layer adhesion issues in this article.

There are many reasons your prints may not be sticking to your Anycubic Kobra bed. These include an uneven print bed, improper nozzle position, wrong temperature settings, or it may just be that your print bed needs the extra support of adhesives.

Anycubic Kobra

If you want to start dabbling or want to replace an older printer, the Anycubic Kobra is a fantastic FDM (fused deposition modelling) printer.

It costs only $300 / £270 / AU$470 from the Anycubic website, which is considered to be pretty affordable. In this price, you’ll have a printer that has automatic bed levelling technology, which is guaranteed to impress both new and experienced printers, as well as simple touch screen controls that make it simple to access all of the printer’s features and settings.

Related: Anycubic Kobra Screen Goes Black? Fixed

Reasons Your Print Won’t Stick to Print Bed

Uneven Print Bed

The first thing you should check is that your printer’s bed is straight and level if it has an adjustable bed and you’re having difficulties getting your first layer to adhere to the bed. Your bed can have one side too close to the nozzle and the other too far away if it is not level. A level print bed is necessary to produce an ideal initial layer.

Although this problem does not occur as frequently in printers which have an auto bed leveling system such as the Anycubic Kobra, it may still be worth looking at.

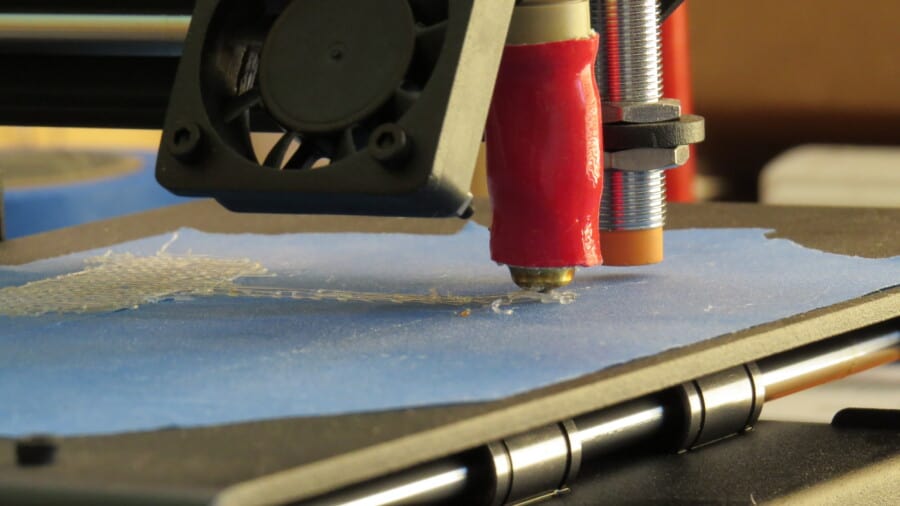

Nozzle Position

You must still check that the nozzle is initiating at the proper height in relation to the print bed once your bed has been properly levelled. The ideal location for your extruder to be in relation to the build plate is one that is neither too far nor too close. You want your material to be somewhat compressed against the build plate for maximum adherence.

Related: How Often Should You Change Your Nozzle?

Temperature

As plastic starts to cool from a high temperature to a low temp, it begins to contract. Imagine a 100mm wide ABS plastic item being printed as a handy example. It is conceivable that the plastic would soon cool after leaving the heated nozzle if the extruder had been printing this plastic at 230 degrees Celsius onto a cold build plate (or 446°F). Additionally, there are cooling fans that, when activated, accelerate the cooling process. The 100mm wide ABS item would shrink by roughly 1.5mm if cooled to room temperature of 30°C (86°F).

Unfortunately, because it is normally maintained at a fairly consistent temperature, the build platform on your printer won’t shrink by quite this amount. This causes the plastic to have a propensity to detach from the build platform as it cools. As you print your initial layer, it’s crucial to be aware of this. It’s conceivable that your temperature and cooling settings are to blame if you observe that the layer initially appears to adhere to the print bed but later comes away from it as it begins to cool.

A heated bed is a common feature designed to print high-temperature materials like ABS in order to address these issues. The first layer will stay warm so that it does not shrink if the bed is heated to a constant 110°C (212°F) during the print. In order to stop the initial layer from cooling, you might want to try heating the bed.

Starting from a basic standpoint, PLA often adheres well to a heated bed of 60–70°C (140-158°F), whereas ABS typically performs better when the bed is heated to 100–120°C (212-248°F).

Adhesives

When all of your bed and nozzle settings have been reviewed multiple times and you are still experiencing bed adhesion issues, it is necessary to bring in some backup equipment to ensure that the print remains attached to the bed. If you are still having trouble getting your 3D print to adhere to the bed, apply an adhesive directly where the filament will touch the bed.

You have a few options to choose from, such as glue sticks, painter’s tape, hairspray, or adhesives designed specifically for 3D printing. By using an adhesive created especially for 3D printing, you can be sure that after your print is finished, the adhesive will come off cleanly.

If you’re using an adhesive, make sure to only put a thin layer over the build plate. Keep in mind that using more adhesive won’t make things better because too much adhesive can cause issues if any remaining residue is left on the print bed after the printing process.

Frequently Asked Questions

What Happens If Bed If the Print Bed Is Too Hot?

If your print bed has a very high temperature, you will likely face problems with the bottom of your print.

Can You Print PLA Without Fan?

A cooling fan is required when printing with PLA. When using PLA, cooling must be set at 100% if you want your print to come out correctly. This is because material must immediately cool down to solidify in order for the next layer to be printed.

Which Firmware Does the Anycubic Kobra Use?

The Anycubic Cobra uses the Cura 4.2.

Related: Anycubic Vyper vs Ender 3(V2/Pro): Which One is Better?

Final Words

So, here you are. If your Anycubic Kobra is facing issues with bed adhesion, it is important to first diagnose the problem before you can look for solutions. In this article, we discussed the various reasons why your Anycubic Kobra may be showing adhesion issues.