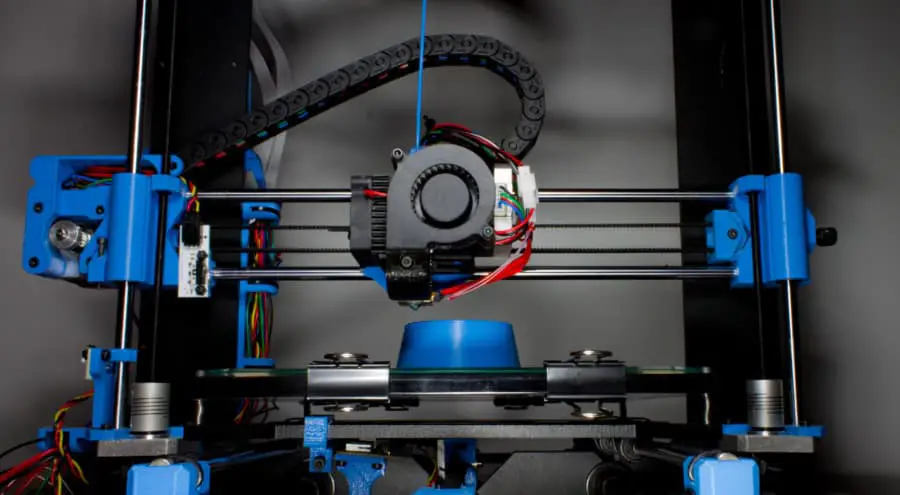

You purchased a Prusa i3 printer, and everything worked great until a couple of days ago. Your objects started resembling art deco pieces instead of the smooth items you require. What do you do when you run a belt status test, and it indicates you have a problem?

Our Prusa i3 belt tension guide provides step-by-step instructions for diagnosing and correcting belt tension issues. We will begin by showing you how to run a self-test and check your belt status. Next, we will walk you through interpreting the results. Then, we will show you to adjust your belts.

Properly tensioned belts are imperative if you want to experience the best 3d printing outcomes. Fortunately, adjusting your belts is a simple process. So, let’s get started by accessing your Prusa i3 printer’s onboard diagnostic tools.

Check Your Prusa i3 Belt Tension Using the LCD Menu

The first step to analyzing potential problems with your 3D printer begins with performing a self-test on your machine.

To perform a self-test, you must go to the LCD Menu on your printer and press Calibration, then Selftest. Once the self-test is completed, return to the main menu and press Support. Then, press Belt Status.

Once you complete this process, the LCD Menu will return with a belt tension rating for your X-axis and your Y-axis.

These two processes look like this:

- LCD Menu—>Calibration—>Selftest

- LCD Menu—>Support—>Belt Status

Evaluate Your Prusa i3 Printer’s Belt Status Readings

Before we discuss your Belt Status readings, we need to explain what those numbers mean. In short, the lower the number, the more belt tension you have on your machine. Inversely, a high reading indicates a looser belt.

For instance, a belt reading of 250 indicates a tighter belt than one with a reading of 280. Simple right? Many people get that wrong, so be sure to remember to take note of this fact. You don’t want to spend time loosening a belt that needs to be tighter.

Remember, a Lower Number = Higher Belt Tension!

Are Your i3 Printer Belts Too Tight or Too Loose?

So, getting back to the numbers, the current user manual for Prusa i3 printers a belt tension range of 240+/-40, which translates to 200 to 280. However, a more current article on the Prusa Knowledge Base website narrowed that range down.

As the author explains, after working with i3 printers and observing them in action, he determined that “the best values seem to be between 255 and 270.” If your printed falls outside that range, you are likely going to have issues with your printer.

Determining How Much to Adjust Your i3 Belts

Before we talk you through adjusting the tension on your belts, we want to provide a little guidance regarding the process. The Prusa Printers Forum has a belt-tightening guide that provides helpful insights regarding tightening your belts.

Although the numbers vary among i3 printer users, the general rule is that tightening the X-axis 2-notches increases the belt’s tension by 25 points.

However, tightening the Y-axis only requires one notch to increase tension 25 points. For example, if you started with a belt tension rating of 275 once you tighten it one click, it should read 250.

Remember, a Lower Number = Higher Belt Tension!

Adjust the X-Axis Belt

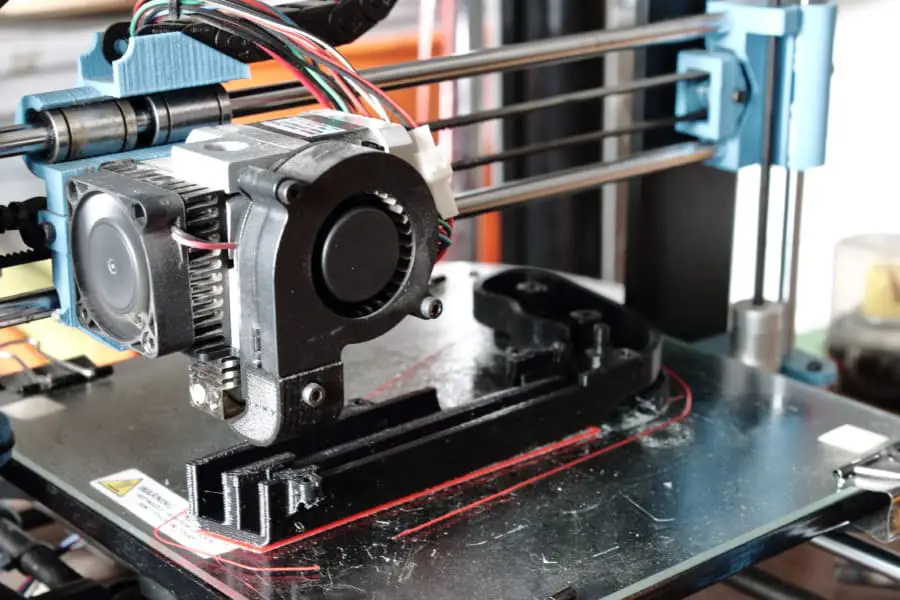

Adjusting the X-Axis is quick and easy, and you can do it with the printer in the upright position.

Materials you will need:

- 2.5 mm hex key screwdriver (An excellent option is the Klein Tools JTH6M25)

- Diagonal cutting pliers (to cut the zip ties, Irwin Vise-Grip 6-Inch Diagonal Cutting Pliers work great for this task).

- Nylon zip ties (OUPENG Multi-Purpose Nylon Zip Ties are a great option).

Follow these steps for adjusting the X-axis belt:

- Turn off the power to your printer and remove the power cord.

- Cut and remove the five zip ties holding the cables to the back of the X-carriage. (Steps 43 and 44)

- Unplug the optical filament sensor cable from the extruder unit.

- Remove all five screws from the back of the rear X-carriage plate and remove it. (Do not remove the two deep-set screws.)

- Take note of the number of spaces in the belt holder, and remove the belt located on the same side as the X-axis motor.

- Firmly grasp the X-axis motor so that it won’t fall. Then, remove the screws holding it into place.

- Remove the belt from the cogged pulley extending from the motor and set the motor aside.

- Reset the belt, noting that every two notches will adjust the tension rating by about 25 points. (Steps 13 and 14)

- Reattach the motor.

- Reattach the plate covering the X-carriage.

- Reconnect the optical filament sensor cable to the extruder unit.

- Attach new zip ties to the cables making sure they won’t hit the power supply when the X-axis is moving.

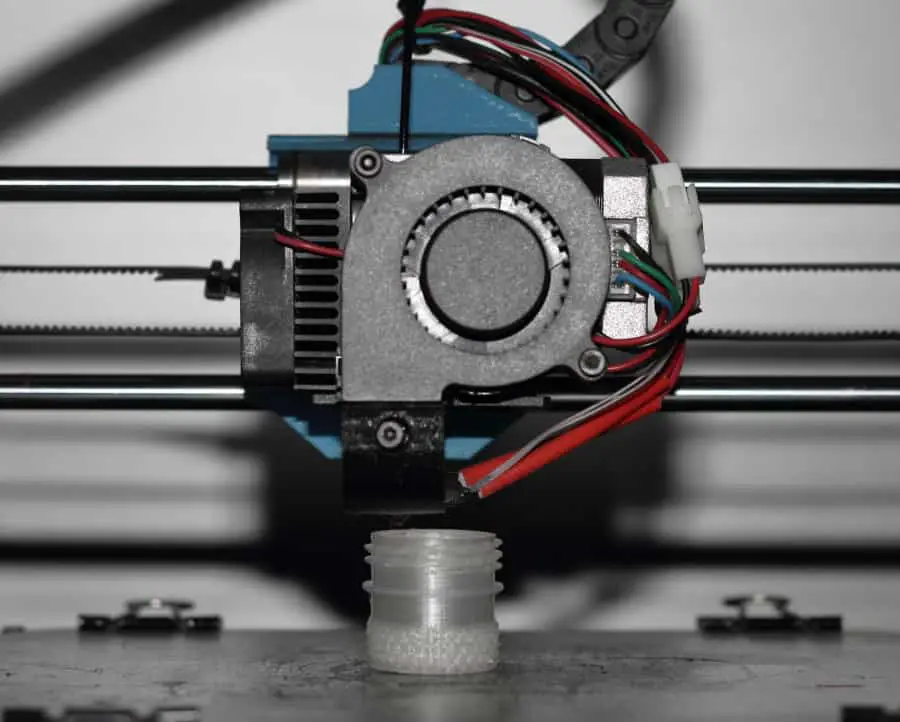

Adjust the Y-Axis Belt

Adjusting the Y-axis is simple. However, you are going to need to turn the printer upside down. If you want, you can print a maintenance stand to help you accomplish this task.

Material(s) you will need:

- 2.5 mm hex key screwdriver

Follow these steps for adjusting the Y-axis belt:

- Turn off the printer and unplug it.

- Loosen the Y-axis belt holders using the hex key screwdriver. Don’t remove the screws. Just loosen them enough to give the belt some slack.

- Take note of the number of spaces in the belt holder and remove the Y-axis belt.

- Reinsert the belt, making sure that you insert the desired number of notches. (Remember every notch changes your belt tension by about 25 points.)

- Tighten the belt holders. (If the tension is too high after you perform a system test, you can always release them slightly.)

Recalibrate Your i3 Printer

- Return your Prusi i3 printer to its upright position once you finish adjusting the Y-axis belt. Take a couple of minutes and perform a visual inspection of your printer to make sure that you didn’t forget to replace any screws. Likewise, make sure you reattached all five zip ties.

- Brush and debris from the machine and give it a quick cleaning using some alcohol prep pads. (Dynarex makes Sterile Alcohol Prep Pads that are ideal for this purpose.)

- Then, all you need to do is recalibrate the machine, perform a self-test, and check the belt status. If everything is good to go, you are done for the day.

The following video from the official Prusa YouTube channel shows you some other ways to improve the quality of your 3d prints:

Points to Remember When Adjusting Your Prusa i3 Printer’s Belts

There are a few important points to consider when working with the belts on your 3D printer:

- Belt tension does decrease over time. Some users report losses as much as 8 to 10 points within the span of a few days. However, that decrease will slow down after a few days.

- When setting the tension on your belts, try to get it as close to the same on each axis as possible. You aren’t going to be able to get it exact. But, try to get the numbers in the same ballpark.

- Be careful to follow the recommended belt tension figures noted above. A belt that is too tight can damage the moving parts of the printer or the belt itself.

- Be sure not to overtighten the zip ties and make sure they don’t hit the power supply.

Conclusion

We hope you enjoyed our article about adjusting the belt tension on your Prusa i3 printer. Three-dimensional printers are complex and expensive machines. For that reason, you will want to take your time and follow each step in order.

However, adjusting belt tension is not as daunting of an experience as you might think once you get started. Additionally, if you have any questions along the way, the Prusa Printers Forum is just a click away, and there are a lot of savvy i3 users available there to assist.

You might consider bookmarking this article since adjusting belt tension on your Prusa i3 printer is required several times a year, depending on how much you use it.