In recent years, 3D-printed weapons have gained both popularity and advancements, enabling individuals to produce more durable and dependable gun parts. We made the decision to write an article on the finest material for 3D-printed firearms, including suppressors, lowers for the AR-15, and others.

High-temperature or reinforced Nylon is the ideal material for 3D printing guns. Since nylon is so robust and resilient, it can survive the heat and strains that the gun produces for a longer amount of time than other materials. You may also use PLA+ or polycarbonate because they work well and are rather sturdy.

Read on to find more about the materials you can use for 3D printing guns!

3D Printed Gun Models

A 3D printed handgun is made wholly or partially with a 3D printer. Fully 3D printed (F3DP), hybrids, and parts kit completions (or parts kit conversions – also abbreviated as “PKC”) are the three categories of 3D printed guns.

A 3D printer can be used almost exclusively to create some weapons, such as the Liberator. As the name implies, these wholly 3D-printed models are made almost entirely of printed plastic. They might drive it with a rubber band and use a nail as the firing pin, but all the pressure-bearing components are printed. They are believed to be of limited use as a result and break regularly after a certain number of bullets if even any at all.

Following the Liberator, several F3DP models, including the Songbird, the Washbear, and the ZigZag, have drawn considerable interest.

Hybrids, on the other end, combine non-printed, professionally made, and some 3D printed components—typically the frame and bottom receiver. Notable among these are the FGC-9, Scz0rpion, Glocks, and variants based on the.380 Luty machine pistol, and firearms in the AR-15 and AK-47 styles.

Parts kit completions are kits that utilize completed or nearly completed parts and demand that the customer print or purchase the missing parts individually.

Some US gun sellers specialize in selling kits that don’t even need to be 3D printed, offering “80% receivers” or “unfinished receivers” in their place. These need to be finished at home with extra tools, which often come with the kit.

4 Best 3D Materials for Guns

High-Temperature Nylon

The High-Temperature Nylon filament is just superior to all other materials in every way. It is constructed of nylon that has been mixed with materials like carbon fiber or glass.

These additions boost Nylon’s toughness, making it nearly as durable as a typical injection-molded object. High-Temp Nylon can endure temperatures of up to 120°C or 248°F without melting, and it has exceptional heat resistance.

Due to the fact that this filament must be printed at temperatures between 285 and 315 °C (or 545 and 599°F), you might need to switch to an all-metal nozzle and an enclosure in to finish the print properly.

Related: 3D Printer Filament Keeps Snapping? Here’s What To Do

Low-Temp Nylon

The absence of the additional reinforcing elements makes low-temp nylon merely high-temp nylon. It is nevertheless remarkably resilient and powerful.

Its extremely high tensile and yield strengths also make it less prone to deformation and unexpected fracture. This is a really helpful attribute considering the amount of stress gun designs frequently experience.

Also, printing on it is simpler than on High-temp Nylon. You won’t need to use an all-metal nozzle, but you will still require an enclosure.

PLA+

PLA is one of the most commonly utilized polymers in 3D printed firearms since it is inexpensive and simple to create. Nevertheless, because of its low glass transition temperature, the majority of users have found that it is fragile and melts quickly.

Therefore, most users have converted to PLA+, a far better version of PLA. In this form, PLA+, additional additives have been added to PLA to enhance its physical capabilities.

All of the positive aspects of PLA, such as its environmental friendliness, are combined with new ones, such as enhanced strength, flexibility, and temperature resistance.

As a result, PLA+-printed gun parts are superior to and more robust than PLA-printed ones. Although it is not as strong as Nylons, it is still less expensive and ought to work fairly well.

Polycarbonate

Another filament that can be used to manufacture quite powerful gun designs is polycarbonate. It has good temperature resistance and is robust and long-lasting.

Additionally, it possesses outstanding stiffness and tensile strength, which enable it to withstand significant strain before succumbing.

Having said that, it does have one really important flaw—it is difficult to print. High printing temperatures and an enclosure are needed to print on polycarbonate.

In order to build a firearm out of polycarbonate, if you don’t already have one in your printer, you’ll need to switch to an all-metal hotend and buy an enclosure.

On another note, it’s guaranteed that the print quality you receive will be worthwhile.

Technology

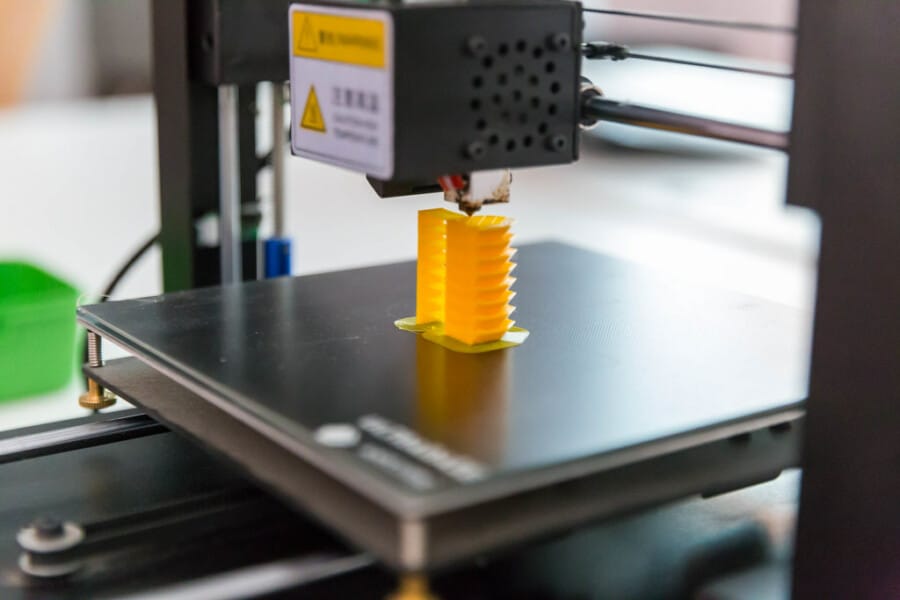

A typical desktop FDM (Fused Deposition Modeling) printer can be used to create the printed components of a 3D-printed firearm. Using thin plastic extrusion, this technology creates a 3D model by adding layers on top of each other on a build plate.

Vat polymerization 3D printers, as an alternative, solidify liquid resin photopolymer using UV light. The materials are often extremely brittle; however, a wider variety is improving this in recent times. They are becoming more and more popular for personal 3D printing. Uniformity, with durability in all print directions, is one benefit that vat polymerization has over FDM prints.

Related: Do 3D Printers Come With Software? Here Are the Facts

The parts you print might take many different shapes. While it is possible to export CAD data and related file types from design tools, most users acquire designs as STL files from the internet or build them from scratch. Once these files have been processed by slicing software, which specifies the 2D “slices” that the machine should adhere to, a machine-readable file that can be loaded onto the printer for printing is produced.

3D Printed Barrels

A gun barrel can be safely 3D printed, although they often don’t last many shots because of the high force needed to fire consistently. A 50-round 3D printed gun barrel has been successful for some users, while it has failed for others or exploded after only a few rounds.

When a gun is shot, the bullet is propelled out of the barrel by the explosion and expanding gases, which create extremely high pressures and temperatures. Typically, thermoplastic filament-printed gun barrels can’t withstand this for very long.

It is conceivable that the barrel will eventually collapse under these pressures and temperatures by exploding or disintegrating.

3D Printed Ammunition

Using an FDM printer, you can create bullet rounds. Many users have manufactured ammunition successfully using materials like PLA and ABS. But there is a catch to this. Bullet casings and starters cannot be 3D printed using thermoplastic filaments. Just the tip of the slug or bullet can be 3D printed.

These 3D-printed rounds are less harmful because they normally move more slowly than their metal alternatives. People utilize them for non-lethal purposes like range shooting and non-lethal ammo for law enforcement as a result.

In addition to printing ammo, 3D printers can also manufacture gun magazines. Among users of handguns, a variation known as the Menéndez magazine is gaining popularity.

Unfortunately, particularly when printed with PLA, it is not as dependable as conventional magazines. They also require metal springs to function.

The strength of decentralized production that 3D printing offers is perfectly exemplified by 3D-printed firearms. Additionally, choosing the right material is essential for a quality gun.

But always keep in mind that enormous power also comes with great responsibility. While printing and testing these weapon parts, always use safe shooting practices.

Related: How Small Can a 3D Printer Print?

3D Printed Guns and Melting

Yes, 3D-printed handguns can melt, albeit it mostly depends on the material used to build them and the circumstances surrounding their use. Typically, 3D-printed components like lowers have excellent insulation against the heat generated in the chamber and barrel. However, the cannon may melt if these components produce too much heat.

Based on the material you used to print the gun, it may also melt if exposed to direct heat for an extended period of time.

High-quality materials with great heat resistance include nylon and polycarbonate. Contrarily, materials like PLA are prone to melting when exposed to direct heat.

Frequently Asked Questions

Does nylon need cooling?

Although some people use minimal fan settings with decent results, nylon does not require a cooling fan to generate excellent 3D prints. Since Nylon is a high-temperature filament that is susceptible to warping, it is not typically advised to use a cooling fan with it. When incorporating cooling, a closed print area is optimal.

Does nylon need a heated bed?

When using nylon filament, a heated bed is necessary for printing on glass. The best way to increase bed adhesion is with a glue stick made of PVA.

Is nylon safe to print?

It is advisable to have an air quality monitor and ample ventilation in any 3D printing setting. However, since nylon’s VOCs are poisonous, it becomes important when printing with nylon.

Final Words

This article discusses most of what you need to know about 3D printed guns and if you should consider manufacturing them. When it comes to firearms, it’s important to always make an informed decision and we hope this article can help you do that.