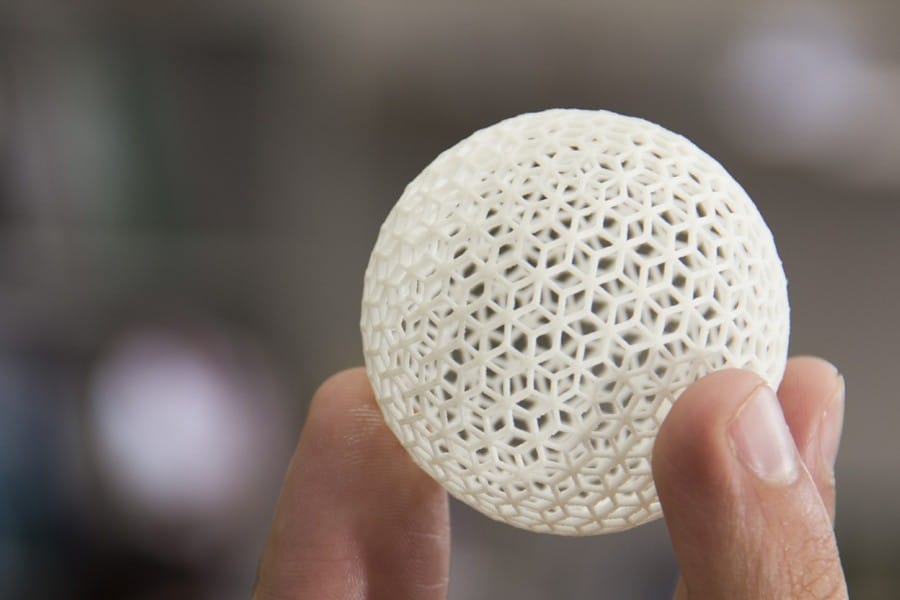

Printing small-scale 3D models with a 3D printer may be challenging because resolutions are not the same as the resolutions you use for two-dimensional pictures and for printing images on paper. Using your 3D printer in creating very small models or models with very fine features and details may involve a steep learning curve for new users. But as to how small your 3D printer can go, it depends mainly on its technology.

An FDM 3D printer can print 3D models as small as its nozzle diameter, which is at least 0.15 millimeters. Resin 3D printers like DLP and SLA can print much smaller details as it offers very fine Z resolutions. With resin printers, you can choose layer height options from 25 to 300 microns.

This article will discuss the differences in various types of 3D printers, especially in terms of their printing accuracy and their ability to print fine details. You will understand how their different 3D printing technologies and mechanisms affect the quality of their print output.

Most Common Types of 3D Printers

Different types of 3D printers use different printing technologies, processes, and materials, influencing their print accuracy and minimum feature size. The most common are:

- Fused deposition modeling (FDM) 3D printers, also known as fused filament fabrication (FFF) 3D printers

- Stereolithography (SLA) 3D printers

- Digital light processing (DLP) 3D printers

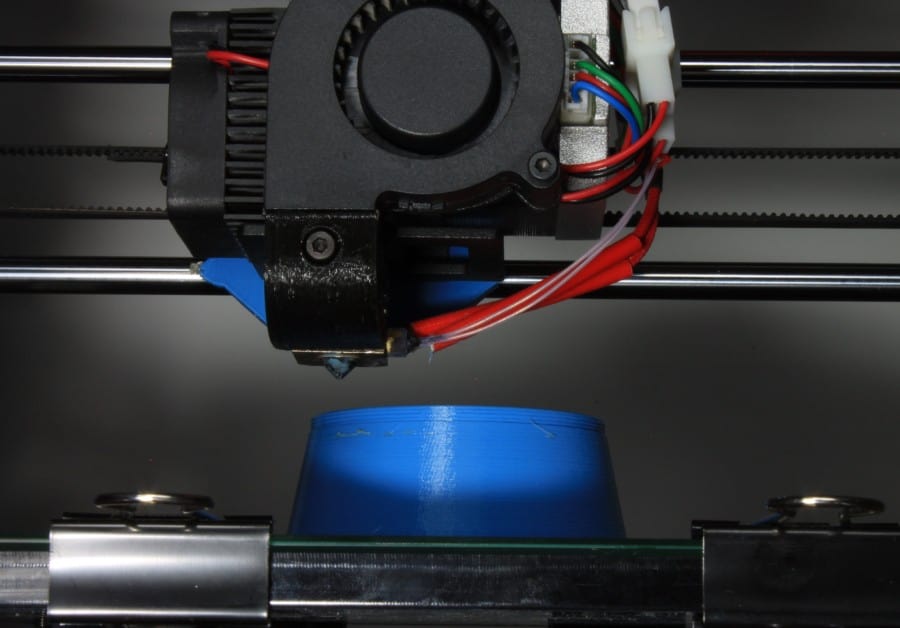

FDM/FFF 3D Printers

FDM or FFF 3D printers extrude thermoplastic filaments like polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS) through a heated nozzle, which melts the plastic and applies layer upon layer of the molten material to create a form. The FDM printing process is widely used at the consumer level.

One advantage of using FDM is that three-dimensional printing models are easy. Once you calibrate your printer and upload your CAD file, the printing process begins with just a push of a button. FDM printing is also a speedy process, and the technology can cost-effectively print objects in low quantities.

However, FDM 3D printing is not known for turning in long-lasting and durable products because each one is created in multiple layers instead of a single piece. There are bound to be weak spots in applying the layering technique. Additionally, FDM’s thermoplastics cannot withstand extreme conditions, so they would melt or deform when exposed to hot environments and crack when exposed to cold.

FDM 3D printing is also not able to produce models at a fine resolution. Because of the layering method, the output tends to have rough edges and surfaces and may require sanding and other finishing to smoothen them out. The tolerances are larger, too, which could lead to multiple prints of similar parts having inconsistencies and significant differences.

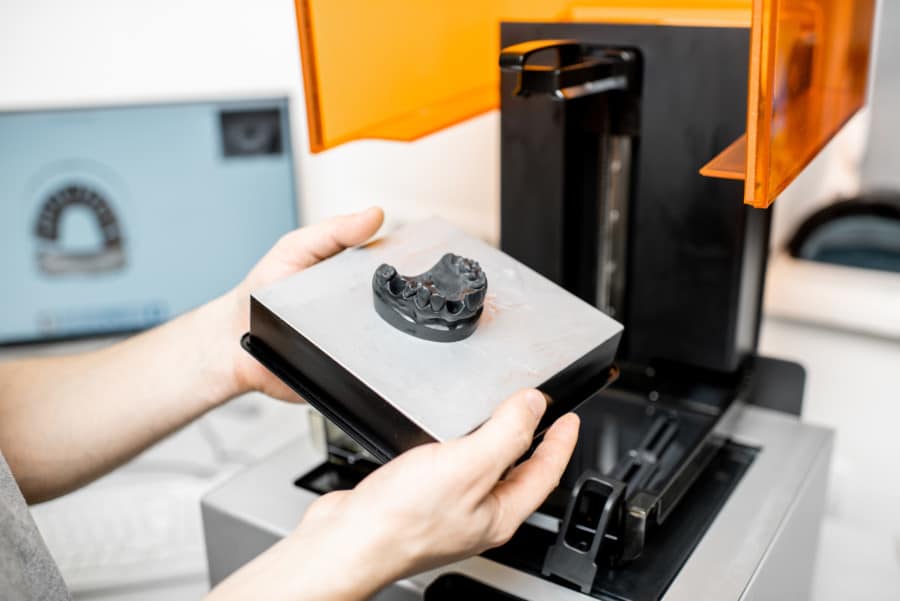

SLA 3D Printers

An SLA 3D printer is a resin 3D printer that produces high-accuracy, watertight, and airtight prototypes and models in advanced plastic materials. It is known to print 3D models with smooth surface finish, fine features, and highly detailed designs.

With a highly precise laser, an SLA 3D printer delivers light to form and cure thin layers of liquid resin that stack up to form one solid object. The process of curing resin into hardened plastic is called photopolymerization. SLA resin formulations boast a broad range of thermal, optical, and mechanical properties that make them ideal for industrial and engineering thermoplastics applications.

Using light instead of heat to print prototypes make SLA reliable. By printing three-dimensional parts at close to room temperature, you don’t have to worry about thermal expansion and contraction, which can be prevalent when printing via FDM.

These parts and prototype printing using the SLA process are also isotropic, which means that they have high lateral strength levels that don’t alter with orientation.

DLP 3D Printers

Like an SLA printer, a DLP 3D printer also uses resin. It creates parts and models upside down, layer by layer, as its build platform goes down into a resin tank. And while an SLA 3D printer uses a laser as its light source, a DLP 3D printer uses a digital projector screen. An image of a layer’s pattern or shape is flashed across the build platform, and this light cures the liquid resin.

The light gets reflected onto microscopic-sized mirrors that are arranged on a semiconductor chip. This digital micromirror device (DMD), in turn, points the light to the bottom of the resin tank, defining the coordinates where the resin hardens in a particular layer.

DLP 3D printers are among the most precise and accurate 3D printers around, so they are great for highly detailed models. And like SLA printers, they create objects with a smooth surface finish.

How Small Can Your 3D Printer Print?

The different types of 3D printing technology have different minimum feature sizes.

How Small Can FDM 3D Printers Print?

FDM 3D printers can print features as small as the diameter of their printing nozzles. The most common nozzle size for these printers is 0.4 millimeters, so that means the smallest feature they can print is that same size, too. However, third-party nozzle upgrades are available. You can get a 0.15-millimeter nozzle and swap your printer’s old nozzle with it so you could print smaller features.

However, you have to keep in mind that how well a model or 3D figure turns out is also heavily influenced by its shape and the movements that the FDM printer needs to make to print it.

One major problem regarding printing small details with an FDM printer is that you have limited control over when the thermoplastic material starts to flow out from the nozzle and exactly when it stops. As such, an FDM printer will have an easier time creating fine details that are part of a larger object than creating a similar-sized detail on a much smaller object.

How Small Can SLA 3D Printers Print?

The minimum feature resolution for SLA 3D printers relies on the spot size of the laser beam. Because SLA technology does not involve thermal stresses like FDM, it is easier to print tall and thin shapes and very small features.

In 3D printing, you will need to get acquainted with the three dimensions: the X and Y dimensions, the two-dimensional planes, and the vertical Z dimension. The Z resolution is the thickness or height of a layer that the printer can produce.

The laser spot size of the SLA printer determines the XY resolution. The increments by which the laser beam is controlled also affects the XY resolution. As for the Z resolution, resin printers offer a layer height of between 25 to 300 microns.

How Small Can DLP 3D Printers Print?

Just like SLA printers, DLP printers offer a fine resolution. You can also pick a layer height option or Z resolution of anything between 25 and 300 microns. Meanwhile, the XY resolution is defined by pixel, which is the tiniest feature that the projector can print within a particular layer.

However, with DLP printers, there is a trade-off between build volume and resolution. The projector dictates the number of voxels or pixels available. The closer the projector is moved to the optical window, the smaller the pixels get, which increases the resolution of your print. As a result, the available build area also gets limited.

Calibration also plays a crucial role. Unlike SLA printers with the same light source throughout, with DLP projectors, you will need to factor in the non-uniform distribution of light on the build platform and lenses’ optical distortion. This means that the pixels right in the middle of the print object are not of the same shape and size as the pixels on its edges.

Final Thoughts

Generally, SLA and DLP printers can print much smaller features and details than FDM printers. More importantly, SLA and DLP are known for more accurate, precise, and more durable prints of industrial and engineering quality. But that is not to say that FDM technology doesn’t have its own strengths. That is why thorough research needs to be done on the pros and cons of each of these types of 3D printers to know which one suits your specific printing requirements.

Sources

- MH Manufacturing: Benefits and Disadvantages to 3D Printing in Manufacturing

- Pinshape Blog: 4 Things You Need to Know About 3D Printing Resolution

- Quora: How small of an object can a 3D printer print?

- All3DP: How Small Can You Go?

- All3DP: SLA vs. DLP: The Differences – Simply Explained

- Dummies: How to Print Tiny or Highly Detailed 3D Objects

- 3D Printing: How small can I expect FDM 3d printers to print?

- Formlabs: FDM vs. SLA: Compare the Two Most Popular Types of 3D Printers

- Formlabs: SLA vs. DLP: Guide to Resin 3D Printers

- Xometry: What is the smallest feature that you can print?

- Make Parts Fast: What is a DLP 3D Printer?