The availability of ASA filament on the market is a recent development for the majority of 3D printing hobbyists. It may not be as widely available as other filament kinds, but it makes a great 3D printing filament for anything that will be placed outside, such as garden gnomes, planters, or any outdoor fixtures. The print quality of the ASA filament and ABS filament is comparable.

The fact that ASA can withstand more time in the sun without turning yellow, degrading, or losing strength gives it a slight advantage over ABS. ASA can be used outdoors or for more demanding uses because of its ability to withstand harsh climate conditions. ASA also has greater bed adhesion compared to ABS. And although the print quality is comparable, there is a better overhang with ASA compared to the ABS.

Below is a guide to assist you if you have never printed using ASA or ABS filament before.

What is ASA?

For FFF 3D printing, acrylonitrile styrene acrylate (ASA) filament is a thermoplastic substance. Despite not being as common as ABS, ASA has a wide range of possible applications because of its advantageous material and mechanical characteristics. The substance actually resembles ABS in many ways, but it has better qualities, particularly in terms of UV resistance.

Early in the 1970s, BASF introduced ASA as a polymer for the first time under the name Luran S. It was developed in response to the requirement for material with characteristics comparable to ABS but stronger resilience to climate and harsh environments, particularly in the automotive industry.

Chemically speaking, ASA is comparable to ABS with the addition of a grafted acrylic ester elastomer during the copolymerization of styrene and acrylonitrile. This is what has enhanced the material’s UV stability and increased its overall resistance to climate conditions.

Additionally, ASA exhibits good toughness, chemical stability, and aesthetic appeal in filament form. These characteristics, along with the filaments’ exceptional UV resistance, make ASA filaments ideal for demanding use cases including outdoor applications. Tooling, functional prototypes, and end-use parts including external electrical enclosures and fittings, automotive housings, and other items are common uses for ASA filament.

Although ASA is less common than ABS, it is nonetheless offered by a number of filament providers today—often in a range of colors.

What is ABS?

Among the most frequently used polymeric filaments in extrusion-based 3D printing is acrylonitrile butadiene styrene (ABS). The reason is obvious: the filament is simple to work with and exhibits good material characteristics for printed items. Additionally, it is easily accessible to 3D printing enthusiasts and professionals alike.

ABS was originally made available for purchase as a polymer by Borg-Warner Corporation in the 1950s. It was primarily manufactured through injection molding until it was used as a 3D printing filament to make durable and lightweight pieces for toys (like LEGO), electronics, pipe fittings, and much more. The material is still utilized for injection molding today, but it is also increasingly being used in 3D printing.

Related: Why Is Your 3D Print Taking So Long? 7 Ways To Speed It Up

The mechanical qualities of ABS filament include strong impact strength, resistance to abrasion, and chemical stability. The low melting point of ABS (about 200°C or 392°F) as opposed to other engineering thermoplastics makes it simple to utilize on most FDM/FFF 3D printers but prevents it from being used in some high-temperature applications.

More importantly, ABS is renowned for having a low density, which makes parts lighter. Because it is lightweight and has strong impact resistance, the material is particularly well-liked in the automotive industry because lighter vehicles have the greater fuel economy. Functional prototypes, tooling, and end-use components are examples of additional applications in a variety of consumer and industrial sectors.

Similarities between ABS and ASA

There are several basic similarities and important differences between ASA and ABS filaments. Which one of the two 3D printing materials you used must depend on these differences. However, let’s begin with what they have in common.

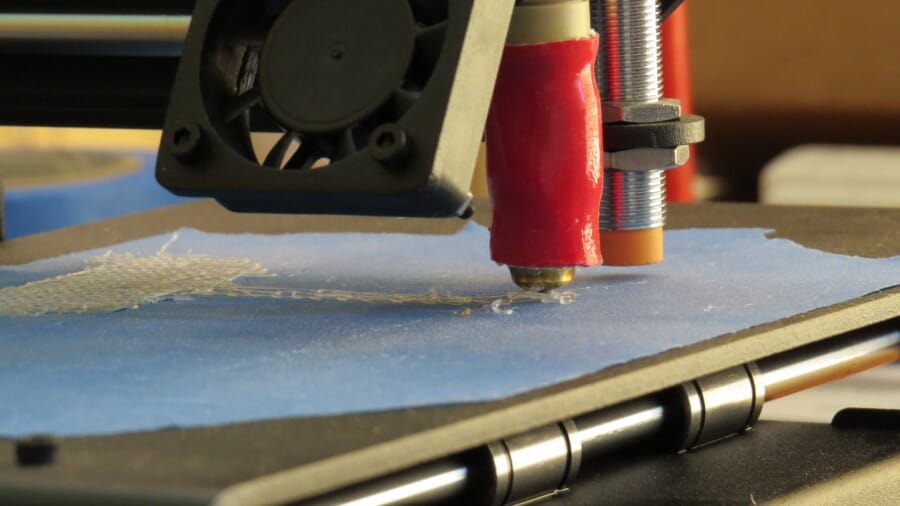

ASA and ABS both share some fundamental characteristics with thermoplastics. In other words, the capacity to melt into a liquid state and then solidify when cooled defines all thermoplastics. Because solid plastic materials are fed through a heated print nozzle (also known as a hotend), which ejects the molten material onto a build plate, this feature is crucial for FFF 3D printing. Layers of the material are extruded, and when the plastic starts to cool, they harden into an item.

ASA and ABS share a few mechanical characteristics, such as high impact resistance and durability, apart from their fundamental thermoplastic nature. This indicates that both 3D printing filaments are suitable for functioning prototypes, jigs, and fixtures, as well as items that are robust enough for production. In contrast to other filaments like PLA, Nylon, and PETG, both materials have high glass transition temperatures (105°C or 221°F for ABS and 100°C or 212°F for ASA).

The filament’s glass transition temperature is the point at which it transforms from a rigid solid state into an amorphous, rubber-like solid. Both ASA and ABS 3D printed items may be effortlessly smoothed down and sanded with acetone during the post-processing phase.

There are a few less desirable characteristics that ASA and ABS do share, including the potential for warping and contracting on the printing platform of 3D printers. If the printed materials cool too quickly, they warp and contract. Due to the material’s contraction and solidification, prints may fail due to inadequate adherence.

Fortunately, precautions can be taken to lessen these dangers, such as controlling the temperature for cooling and printing and enhancing first layer adherence with the help of a heated bed, tape, or specialized adhesives. Despite this, some ASA filament brands claim to have greater layer adhesion and less shrinkage than their ABS equivalents.

Finally, it should be noted that both ASA and ABS should only be utilized in well-ventilated areas. Ventilation is crucial because ASA releases toxic and pungent fumes when it is 3D printed. Additionally, as ABS melts, it releases a hazardous chemical that, if inhaled in excess, can cause headaches and dizziness.

The styrene component of the thermoplastic is responsible for the toxicity in both materials. All of this simply implies that properly installed filtration systems or a well-ventilated environment should be used while using 3D printing materials.

In conclusion, the main parallels between ASA and ABS are:

- Both of these materials are thermoplastics.

- They are robust and have great impact resistance.

- Sanding and acetone are post-processing options for both of them.

- Risks include warping on the build plate.

- Because of toxic fumes, they should only be used in well-ventilated areas.

Differences Between ABS and ASA

The ultraviolet (UV) resistance of ASA and ABS filaments is the most significant distinction to be made. Despite being durable, ABS is known to swiftly deteriorate when exposed to UV radiation. This indicates that the material’s advantages when employed for outdoor applications—where exposure to light is inevitable—are limited.

ABS 3D printed objects can lose some of their natural toughness and integrity as well as their original color when left outside (yellowing is a common symptom).

Contrarily, ASA was developed with UV resistance in mind. Therefore, the 3D printing filament is perfect for outdoor applications and more demanding use. Furthermore, ASA filaments are more moisture-resistant than ABS, which further shields them from the outdoors and bad weather.

Standard ABS filaments are less temperature resistant than ASA filaments, resulting in both clear benefits and drawbacks. Firstly, applications that call for improved heat resistance, including those for heat-stressed components, are ideally suited for ASA.

However, ASA has a drawback in that it needs higher print temperatures to operate, which uses more energy than ABS filaments and raises operating expenses. Having said that, enclosed and temperature-controlled 3D printing systems are advantageous for both ABS and ASA.

The second distinction between ASA and ABS—material cost—is a critical one for many 3D printing users. ABS is among the most affordable thermoplastic materials for FFF 3D printing and is also one of the most widely accessible. ASA material typically costs more because it is a more recent and specialized introduction into the filament market.

ABS is preferable in some circumstances because ASA spools can be prohibitively expensive, especially for hobbyists. However, in situations involving industrial or professional use, the extra cost might be worthwhile given the advantages of UV resistance.

In conclusion, the main distinctions between ASA and ABS are:

- Compared to ABS, ASA is more UV resistant.

- Unlike ABS, ASA is more water-resistant.

- In comparison to ABS, ASA is more temperature resistant.

- ASA filament is more expensive than ABS.

Warping

When a 3D-printed object does not cool down evenly, warping or curling can happen. As we all know, cooling creates contraction, and this specific process puts stress on the part’s lateral surfaces. The load on your 3D printed object’s lateral sides increases with how quickly it cools down. The corner at which two of the edges from your 3D print join is where this stress is at its highest. Consequently, this causes distortion or a pull-up shape. You might find the outcome disappointing in the end.

Related: Bed Adhesion: The Ultimate Guide

This could be a serious problem with the ABS filament prints unless you use an enclosed printer.

In addition to this, there is another problem that lowers the quality of ABS filament. Cracking is a phenomenon that resembles warping. This problem appears near the top of the print. Remember that cracking and warping can both degrade the quality of your 3D print. Not only are the mechanical properties of the warped or cracked parts inferior to those of correctly bonded layers, but it’s also about appearance.

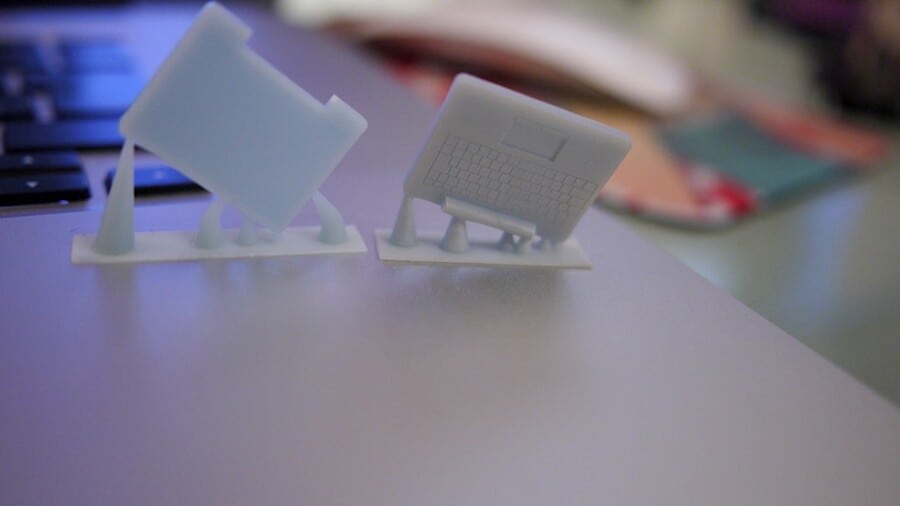

Esun ABS+ vs ASA Comparison

eSUN is the world’s leading manufacturer of 3D printing filaments. It is based in Shenzhen, China. It provides quality filaments at cheap prices internationally. Among their most popular products are the ABS+ and the ASA filament.

If you look at the official eSUN website, you’ll find that both the filaments have very similar properties but there are some key differences. For example, the heat distortion temperature is only 54°C/129°F for ASA whereas it is 73°C/163°F for ABS+. The ABS+ also has twice the impact strength (42°C or 107°F) of ASA (19°C or 66°F).

The ASA is also UV resistant which is why it’s more expensive than the ABS+. The printing temperature is 220 to 260°C (or 428 to 500°F) for both filaments. The recommended bed temperature is also the same at 90-110°C (or 194-230°F).

Both the filaments come in a nice, well-packaged spool. Basic information for appropriate use of the filaments is written on the packaging of the filament. The ASA comes in transparent packaging whereas the ABS+ does not. The ASA only comes with a sticker with bare essential details and information such as the printing temperature provide.

The bed adhesion for both the ASA and ABS+ is great, especially if you provide your 3D printer with the extra support of adhesives. However, the layer adhesion for ASA is much better than that of the ABS+.

The bridging and stringing are similar at the same temperatures for both ASA and ABS+. However, the overhang is much better on the ASA. It’s also a more shiny filament compared to the ABS+.

Removing the prints from the print bed is also fairly easy for both the ABS+ and ASA. All you have to do is make sure to wait until the bed has cooled down.

The layer adhesion is similar for both filaments for the most part. However, the ASA is much stronger than the ABS+.

How to Print Effectively with ASA?

Make Sure the First Layer Is Correct

Although ASA filament exhibits less warping than ABS, it nevertheless can exhibit some warping. Make sure the printer has been calibrated correctly to produce the foundation layer to guarantee there are no warping issues. Your print bed needs to be properly leveled. Additionally, you must ensure that the space between your printer’s hotend and the bed is level.

Build with a High-adhesion Print Bed

If your printer doesn’t have a high adhesion print bed, using ASA filament will not be an option for you for a very long time. This is because ASA needs high temperatures to prevent cracking brought on by thermal deformation.

The hotbed must be kept at a temperature between 80 and 100°C (or 176 and 212°F). Additionally, you can focus on enhancing adhesion by employing a specific type of stick glue or lacquer for 3D printing.

Correct Temperature Calibration

The melting point of ASA is between 250 and 260°C (or 482 and 500°F). For this reason, the printer’s hot end needs to be modified to maintain this temperature.

Related: Do 3D Printers Come With Software? Here Are the Facts

Frequently Asked Questions

Is ASA strong than ABS?

ASA offers stronger heat resistance and mechanical qualities that are on par with or better than those of conventional ABS. Additionally, ASA exhibits remarkable UV resilience and provides the best aesthetics of any FDM thermoplastic thanks to its matte surface.

Is ABS easier to print than ABA?

Although the ASA comes with many advantages over the ABS, notably the UV resistance, it also comes with increased printing difficulty which may be important to users who are just starting out with 3D printing.

Is it possible for the ASA to warp?

Although ASA filament exhibits less warping than ABS, it nevertheless exhibits some warping. Make sure the printer has been calibrated correctly to produce the foundation layer to guarantee there are no warping issues. Your print bed needs to be suitably leveled.

Does ABS degrade over time?

The mechanical qualities of ABS, including impact strength and elongation to break, degrade over prolonged exposure to heat and oxygen as a result of polymer degradation, leading to premature failure.

How fast should you print ASA?

Start printing at 50mm/s and only raise the speed once you are satisfied with the print quality. Keep your part firmly attached to the bed by printing your first layer at 25 mm per second. Start moving at a minimum of 150 mm/s, although 300 mm/s is preferred. Maintain the highest setting that your printer will allow.

Final Words

In the end, both ASA and ABS are 3D printing filaments that come with advantages of their own. High impact resistance, durability, and weather resistance are all features of ASA. High impact resistance, toughness, and better usability are all features of ABS. ASA is normally more expensive, whereas ABS filament spools are typically less expensive.

What matters, as previously stated, is how you intend to use the material. ABS is generally a wise choice if you’re planning to 3D print a prototype or enclosure for indoor use. On the other hand, ASA is by far the superior choice if you are working on a project to create a useful prototype or end-use product that will be used outside and will benefit from UV stability. It’s a good idea to make sure the material is appropriate for the 3D printer you’re using.