Both new and experienced 3D printer owners may find it alarming to hear a few strange clicking noises. But 3D printer users frequently experience such noises, which typically indicates a problem with the filament flow.

The extruder gear is left immobile while the stepper motor continues to rotate, which is probably what is causing the clicking sound. The motor may be “skipping” for several reasons, including a clogged nozzle, debris caught in the extruder gears, or incorrect printer settings. Finding a fix entails accurately diagnosing the issue first.

It’s important to know what you can do to fix clicking sounds in your printer because there are so many potential causes. These causes and potential solutions to the issue will be covered in this article.

Common Fixes

Dirt & Debris

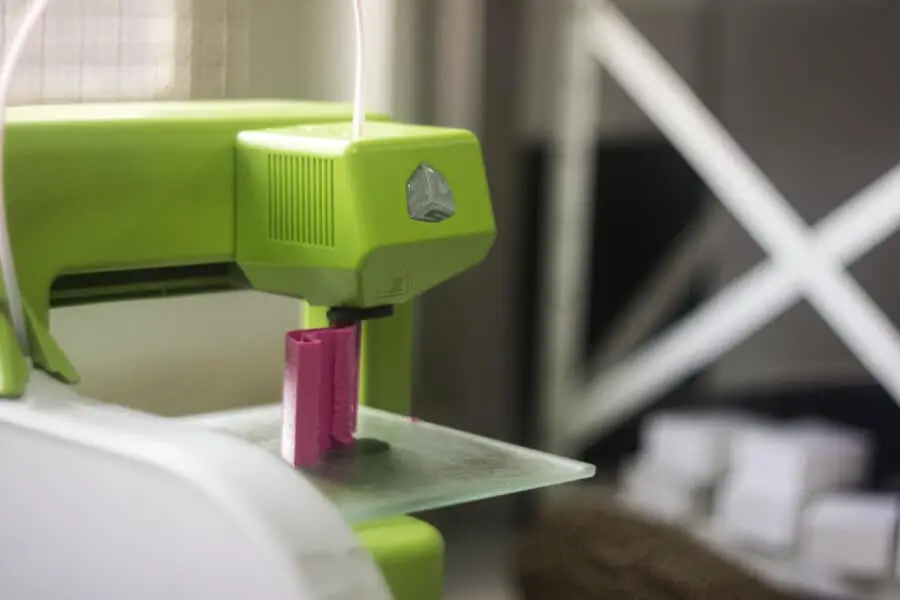

The extruder is responsible for feeding and removing the plastic filament from the printer. The extruder generally has two components: hot and cold. The cold section pulls through the hard plastic as the printer creates the shape of the product, and the heated component processes and melts the plastic.

An accumulation of dirt or dust may lead the extruder to skip or slide over some filament. One of the moving parts could become stuck if dust and other debris pile together. Even worse, the filament’s protective dust can be pulled into the extruder and hardened into a clog as it burns at the nozzle.

Cleaning the extruder after usage is an essential maintenance procedure. If the extruder isn’t used frequently, you might want to clean it once weekly.

Related: Anycubic Vyper vs Ender 3(V2/Pro): Which One is Better?

You should wipe the extruder’s exterior with a moist towel to clean it. It could be necessary to clean the interior of the nozzle. A cleaning filament can assist in removing nozzle obstructions. It eliminates thick buildup that is otherwise challenging to clean and is efficient and simple to use.

To keep unused filaments free of dust and debris, store them in sealed containers or plastic bags. Clean them off with a mildly moist towel before using them. Keep unused filaments away from the area where work is being done.

Damaged Motor

The component that drives the feeder, and transports the material to the print head, is known as the feeder motor. A clicking sound may be produced by the feeder if the motor is wearing out or malfunctioning.

It might be necessary to adjust the motor. You will need to check that everything is securely attached if the motor is loose. Examine the connecting pins to make sure they are properly placed and aren’t shifting.

You can also replace the motor. Remember to turn off the electricity before you do anything. Don’t throw any of the parts away. Make sure the replacement feeder motor you buy is suitable for the Anycubic Vyper. You could either look for information on how to change the motor yourself or take it to a shop to get it done properly.

Damaged Stepper Driver

The circuit that powers the stepper motor is known as a stepper driver. Damage to the stepper driver can cause voltage and current to vary, which disrupts the printer’s timing. Unusual stepper motor movement is among the first signs of potential issues.

Examining the wiring is one of the first steps in figuring out if there is an issue with the stepper driver. Remove the filament first, then turn on cold extrusion on your printer. The wire connection can then be properly tested. You may have a wiring problem if you jiggle a wire and the motor skips or behaves erratically.

Stepper motors also frequently experience problems with overheating. The motor may get heated if an excessive voltage is applied to it. When that occurs, it can slow down or stop entirely. To make sure the electricity isn’t flowing wrongly to the motor, inspect the stepper driver. If the driver is the issue, you can either have the printer fixed by a professional or purchase the necessary parts on your own.

Incorrect Slicer Settings

The 3D printer’s slicer is responsible for compiling all the important data and sending it to the printer for printing. The printer hardware, supplied data, and slicer settings are carefully synchronized. The printing speed may be affected if the slicer settings aren’t compatible with the printer hardware.

Related: How to Fix Anycubic Kobra Not Reading SD Card

Make sure your slicer’s settings are suitable for the print you’re attempting to finish. Adjust them if necessary if they aren’t. Make sure to adjust the parameters in accordance with the Anycubic Vyper.

Nozzle Too Close

You may have noticed that your printer begins printing only as the bed lowers. A clogged extruder may be the cause of your printer’s failure to print the first couple of layers. If the bed is too near, the molten filament risks getting jammed in the extruder. You can address this issue in a few different ways.

The Z-settings (also known as Z-axis settings) are located in your G-code settings. Without altering the hardware, you can make some slight printing adjustments by tweaking the printer’s Z-axis. Slowly make the changes until the filament is running smoothly.

The printer bed may also be adjusted manually. Simply level the bed enough for the filament to attach to the bed without running back into the nozzle. An excellent tip is to set the bed in a way that a regular sheet of printer paper can fit there with only a little friction.

Related: Why Is My Anycubic Kobra Not Sticking to Bed? Answered

Frequently Asked Questions

Can moist filament cause nozzle blockage?

Nozzle obstruction is one of the most annoying problems that are the direct result of moisture in filaments. If the filament has somewhat expanded, it could result in a nozzle obstruction in the printer.

Can acetone dissolve PLA?

Acetone can dissolve PLA, but only in specific circumstances.

How long can PLA sit outside?

PLA can withstand exposure to direct sunshine for one week at room temperature before it turns brittle. Although they can result in poor prints, PLA filaments subjected to more than 60% humidity can last for less than a month.

Final Words

A 3D printer may create a clicking sound for several reasons, including trapped filament, a faulty feeder motor, or a clogged nozzle. The majority of these issues may be resolved at home by modifying the printer’s settings and making sure that every component is properly cleaned, fastened, and working.