One of the common problems you would experience with your 3D printer is its thermoplastic filament snapping. This happens when there are moisture issues, mechanical stress, or issues with filament quality. The good thing is that there are various ways to fix this problem and prevent it from happening in the future.

If your 3D printer filament keeps on snapping, you may need to store your filament properly, dry it out and keep it moisture-free, or buy one of better quality. However, it is also important to determine why your filament snaps so you would know which solution will effectively stop the problem.

This article will discuss in more detail the different reasons why a filament keeps snapping. You will also have a more in-depth idea of what to do to prevent it and keep your filament in tip-top shape for your 3D printing projects.

Reasons Why 3D Printer Filament Keeps Snapping

Thermoplastic filaments snap because they get brittle. And there are three leading causes for this happening. Any one or a combination of any of these causes might explain why your filament breaks.

Moisture

Over time, the filament absorbs moisture from the air around it, especially in highly humid environments, and this causes certain changes in its physical properties. Eventually, this reduces the filament’s flexibility. In most cases, the outer portion of the filament reel, which is the part that gets exposed to moisture, would start getting brittle and would break.

One good tell-tale sign that your filament is full of moisture is that it creates a rough surface after printing. It also makes a popping, hissing, or cracking sound when extruded.

Mechanical Stress

A filament gets straightened in the 3D printing process after a long time of being curled around its reel or spool. This curling and straightening process subjects the filament to constant mechanical stress. Not to mention the additional stresses it goes through during printing. All of these stresses contribute to the filament getting brittle and experiencing reduced flexibility.

The section of the filament that has been straightened is more likely to break.

Low Filament Quality

Not all filaments are created equal. Some manufacturers or brands offer high-quality filaments, while some produce low-quality ones. It all depends on the manufacturing processes they use.

Premium quality filaments possess more flexibility than the others. These products are more tolerant of all the bending and the mechanical stress they go through from curling and straightening.

There are also brands of filaments that seem to offer adequate flexibility while they’re still new or fresh from the store or supplier but then get more prone to snapping over time. The degeneration process of these filaments usually takes months, though, so you shouldn’t get pressured about having to use up your filaments in one go.

Other Possible Reasons

You may also want to consider other possible reasons for your filament snapping and breaking.

For instance, it may be the color additives blended into the filament that could also alter its mechanical properties.

The type of filament is also a factor. For one, PLA or polylactic acid is a relatively brittle material by nature. As such, PLA filaments snap more quickly than other materials or other types, like ABS or acrylonitrile butadiene styrene filaments.

3D Printer Filament Keeps Snapping: How To Fix It

There are different ways for you to fix the problem and to keep your 3D printer filament from snapping.

Store Your Filament Properly

If moisture is the problem, an excellent first step for 3D printer users is to store the filament in an airtight container or in a big vacuum-sealed bag. Good vacuum bags come with a vacuum valve that allows you to get all of the air out of the bag by just using a vacuum cleaner. There are also bags that come with a hand pump so that you could compress them around your filament easily. These reusable bags can protect your filament from water, dust, odor, and other micro-particles.

You may also want to toss in packs of moisture-absorbing silica beads or desiccants into the container. This measure would effectively control humidity and prevent moisture from negatively affecting your filament.

You should also make sure to store your filament away from direct sunlight and not to expose it to drastic changes in temperatures. The best place to keep your filament container would be somewhere relatively cool and dry. Keep that location covered, too.

Dry Out Your Filament

Dry out or cure your filament by using a specialized 3D filament box. This box has a drying and heating mechanism that dries your filament according to your set temperature. You will also adjust the heating or drying time and input the filament type and the humidity.

You can also use these special boxes to store your filaments. They are, however, more costly than vacuum bags.

Reduce Air Moisture

If the moisture level in the air of your home is high, you can reduce it by using a dehumidifier machine. There are dehumidifiers of various sizes and levels, so get one that could cover the size of the room.

The great thing about using a premium quality dehumidifier is that it won’t just benefit your filament. It will also help improve your home’s air quality and perhaps even improve the general health and wellness of your family as it helps prevent molds and allergens from thriving in your indoor environment.

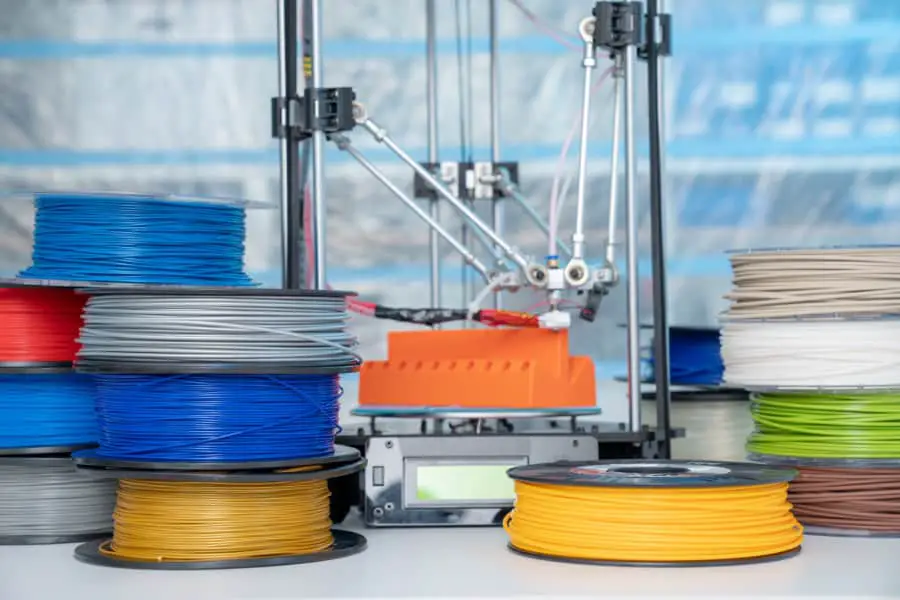

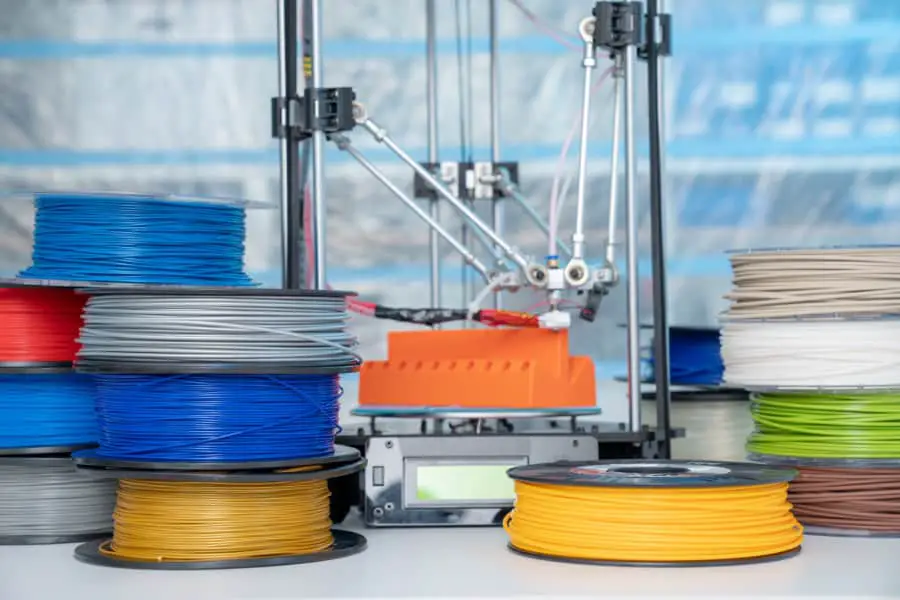

Choose a Filament With Better Quality

A low-quality filament is more likely to snap than a high-quality one. So always make sure to go for the most reliable and reputable brands. If you’re not yet sure about the brand or the product, you can always refer to the reviews left by users.

If you’re still in the process of experimenting with your prints, then don’t hesitate to try out different brands and take note of their differences. Don’t pick a favorite filament brand before you’ve had the chance to test out the other players in the filament-making business.

Aside from the quality of the prints, you should also factor in the price. Ultimately, pick one that gives you high-quality output for the most competitive price. You may also take customer service, colors, and availability into consideration.

Heat Your Filament Roll

ECO suggests heating your entire PLA filament roll in the over to reverse its brittleness. Place the roll in your oven for a couple of hours, making sure that the temperature does not go beyond 122 degrees Fahrenheit (50 degrees Celsius). Then see if the flexibility of the filament has returned without making it soft and rubbery.

To check the flexibility of your filament, you can bend it and see if it does not break off.

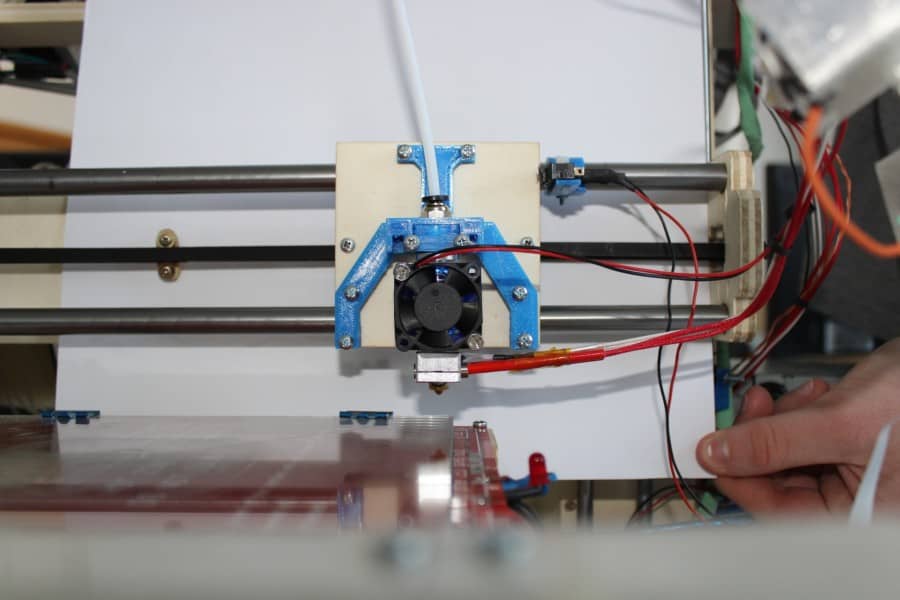

Increase the Temperature of Your Nozzle

You can also try to fix issues with your 3D models or prints by increasing the temperature of your printer’s nozzle. Doing this helps ensure that sufficient heat is applied to your PLA filament so that it evaporates the moisture while also softening the filament’s physical form. You can try a few different heat levels and see which one gives you the ideal value.

Final Thoughts

3D printer filaments snap because they become brittle due to moisture, poor filament quality, or mechanical stress. So, if your filament breaks and you have no idea what is causing the issue, you can try applying different fixes one by one and determine the cause by process of elimination.

You can also apply different fixes at once. In fact, some of the recommended measures should be standard practice. Properly storing your filament and using a dehumidifier to reduce moisture in the air, for example, are beneficial even without filament problems. It’s also good to always opt for high-quality filaments.